Oscillate Wildly

The truth about ovens and temperature, a guest post from Jesse Raub

Table of Contents

As much as maintaining a sourdough starter requires patience, baking successful bread also requires establishing a routine. Once your yeast and bacteria culture gets used to eating a certain thing at a certain time, it likes to lock into a schedule—from then on, consistency becomes your friend. About a year after moving to Madison, Wisconsin, I finally figured out which flour combinations worked the best, my starter had an extremely predictable schedule, and my breads have never looked better—so much so, that I lost the urge to update my breadstagram because every loaf started looking exactly the same. Everything was dialed-in—my standard country loaf flour ratios (5% rye, 10% whole wheat, 20% bolted wheat, 30% malted bread flour, 35% strong bread flour), my overall baker’s percentages (80% hydration, 20% levain, 2.2% salt), and my bake temperatures, too (500ºF preheat, bake at 465ºF). At a certain point, you start to wonder what else you possibly could do to improve the quality of your bread.

And then my oven broke.

Now, I’m not here to promote specific appliance brands or bad-mouth others, but not every oven is made to the same quality standards. As the repairman walked into the kitchen, he took one look at the brand name on the range and said, “Oh yeah, it’s the igniter, and it’ll be $350 to replace. You might wanna buy a new oven because something else on this thing is gonna break in a year or two again.” I’d heard similar sentiments from repairmen at old apartments about the same brand.

What I hadn’t considered, however, is that not all ovens heat the same, either—especially gas ovens.

Once our new range was installed (a mid-priced model from a well-trusted appliance brand that had great reviews online), I noticed something immediately: my bread came out looking better than ever. The spring was bigger and more consistent, the crust browned more evenly and darker, and the crumb structure maintained its integrity for longer on my counter. With my last oven, dialing in the right temperature was difficult—set to 450ºF, the loaves would take almost an hour to fully brown, leading to a thick and tougher crust. At 475ºF, however, the edges would start to burn before the crust took on the right shade. A lot of bread recipes will tell you that some ovens run hot while others run cool, so bake time and temperatures will vary. It’s actually a bit more complicated than that, though.

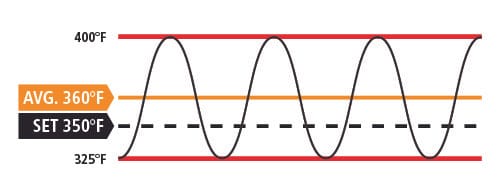

This blog post from ThermoWorks does a pretty good job of explaining oscillating oven temperatures, but I’ll summarize it here, as well. As the oven reaches the programmed temperature setting in its thermostat, the burner will switch off. However, there’s still a lot of carryover from the burner itself, and the oven temperature will continue to rise past the set temperature by anywhere from 15ºF to 50ºF. With the burner off, the oven’s temperature begins to drop. Once it drops to the set temperature, the burner kicks back on, but it takes a little while for the temperature to stabilize again. That means your oven temperature will drop below your set temperature by 15ºF to 50ºF before it starts to climb again.

Better quality ovens program their thermostats to compensate for this temperature swing—they more or less “predict” when the rising temperature will hit your set temperature, and the burner will kick off sooner, coasting to a temperature crest just above your set temperature. They also predict when the falling temperature will pass your set temperature, and prematurely turn the burner on to stabilize the temperature so it doesn’t drop too far below your set temperature. This programming, however, isn’t based on real-time predictive feedback—it’s just modeled after the heating and cooling cycle of that oven model during product testing, i.e. the thermostat is offset to stop at 385ºF when shooting for 400ºF, etc.

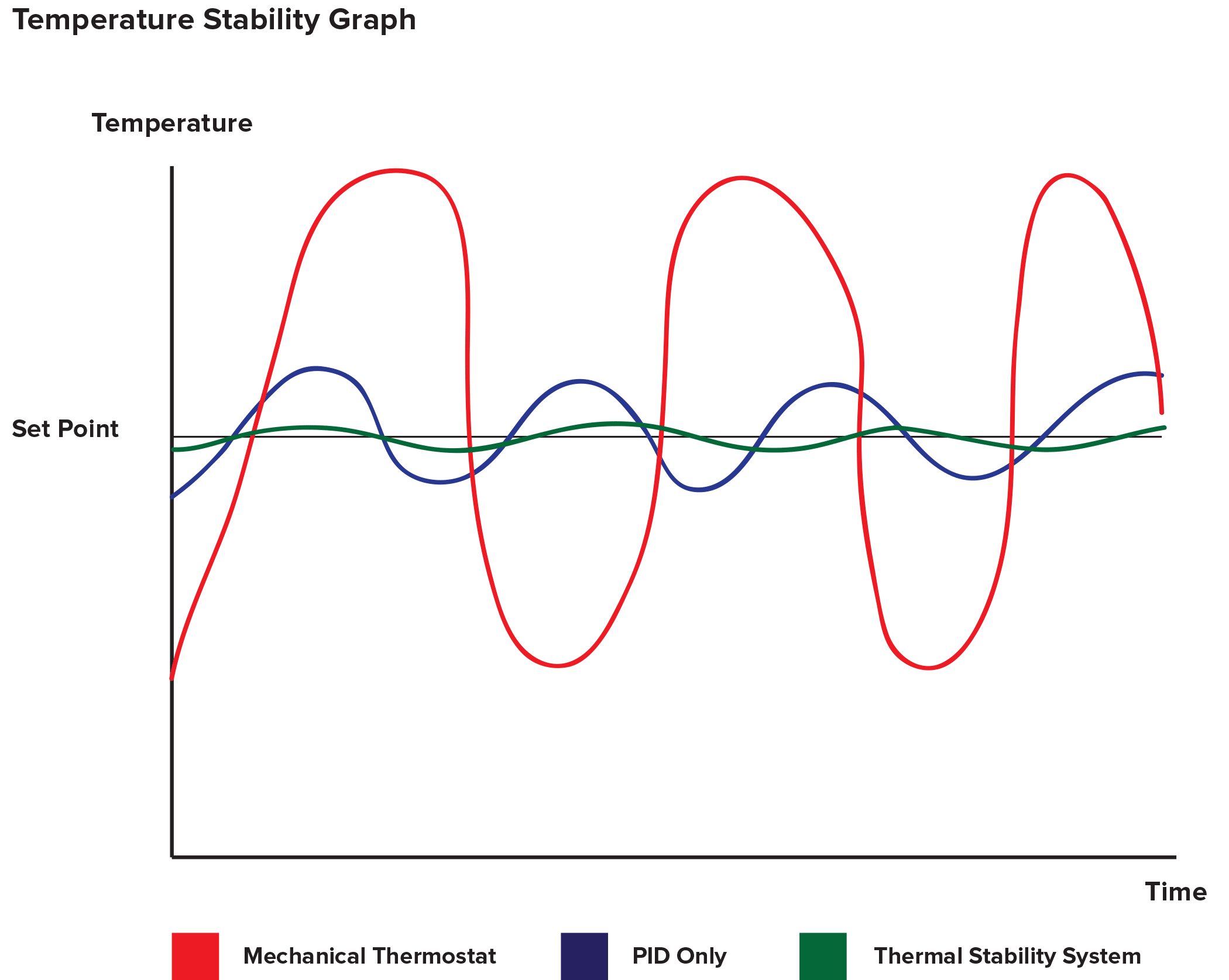

The reason why I’m familiar with these temperature curves is because the same issues exist for espresso machine boilers and I spent 16 years as a coffee trainer and educator. In espresso machines, this temperature swing can be easily corrected by a PID controller (which stands for proportional integral derivative). Essentially, it’s a small computer driven by an algorithm that runs a predictive temperature cycle that was commonly used for tofu production (among other things). The advantage of a PID over a thermostat is that it constantly reads the temperature and can flick the heating element of the boiler on and off dozens of times per second.

The impact of temperature stability on espresso was revolutionary—espresso shots were consistently sweeter and lacked the bitterness that can come from temperature spikes and the flat, sour quality of temperature dips. And while some countertop toaster ovens have adopted PIDs for temperature regulation, it’s just not practical for full-sized ranges that need to heat a bigger space and have more powerful heating elements. As this Q&A states: “a PID controller could in theory turn a battleship on a dime, but the amount of power required of the engines just isn't there to make that happen.”

There’s another elephant in the room that we haven’t quite touched on yet, either: gas burners are a crappy way to heat an oven. When temperature swings trigger an electric heating element, all it takes is a quick surge of voltage to flick on. Gas ovens have an electric igniter that operates the same way as an electric oven’s heating element, only it needs to heat up before the gas valve opens to restart the flame. An electric heating element (say, in an espresso machine or toaster oven) can flicker on and off as much as it wants to; a gas burner in an oven physically can’t do the same thing.

Which brings me back to the comparison of my two gas ovens. When I checked the temperature of my cast iron bread pans or baking stones with an infrared thermometer in my old oven, they would often match the set temperature of the oven. Using a thermocouple’s probe hanging in the middle of the oven, however, the ambient temperature would read around 15ºF to 20ºF less than the set temperature. That’s why I had to settle on a 465ºF bake temperature while most recipes call for a 450ºF oven. I’ve yet to break out the thermocouple to check the ambient temperature of the new oven, but my cast iron pans and baking stones consistently read 15ºF to 20ºF higher than the set temperature, giving me good reason to believe my new oven is more consistent and accurate to the set temperature. Cast iron and cordierite baking stones are excellent at retaining temperature, and since a natural gas burner can reach temperatures up to 3,542ºF, it makes sense that those materials would read higher than the ambient air temperature after absorbing heat from the burner kicking on.

But that doesn’t really explain the quality difference in my bakes. Theoretically, if I offset the temperature of my old oven, the results between the two should be the same. And that’s where trying to apply static data points falls short as an evaluation method. Unless I have five separate temperature probes tracking different parts of the oven during preheating and baking, I don’t really know how consistently the oven is heating up (or maintaining its temperature). So even if the average temperature between the two ovens is the same, the way that heat is applied and the way it moves around the oven isn’t.

So where does that leave us? Well, it’s pretty safe to say that my new oven does a better job of consistently heating my cast iron bread pans and the bread itself. Theoretically, my loaves spring better because they have more consistent heat application, they brown better because that heat is more evenly distributed through the oven, and the crumb structure has better integrity because the browning of the crust is happening more in line with the moisture evaporation from the dough. No matter how much I’d love to attribute this to specific data points on a plotted graph, it doesn’t really matter. My new oven works better than the old oven.

But a new oven isn’t a practical step towards improving your bakes. If I had to make an assessment, I’d say my breads are maybe 10% to 15% better than they were before, and it costs $900 to achieve that jump. While starter feeding ratios, flour choice, and ambient temperature are variables you can play with to achieve the bread quality you’re looking for, swapping out an oven isn’t something you A/B test—the old one is long gone, so any chance of testing them side by side is out the window (or, more accurately, out the front door, carried by two nice men the size of refrigerators).

So if you, like me, are wondering how you can take the next step to improve your bread, a new oven will likely do the trick. But running out to make an appliance purchase for a slightly better crust is a little silly. Besides, if your oven was made by a company better known for manufacturing smartphones and TVs, a new oven is likely in your near future, anyway.

wordloaf Newsletter

Join the newsletter to receive the latest updates in your inbox.